Rapid evaluation of fish texture via system identification and modelling techniques

The Hellenic Centre for Marine Research and the University of West Attica have focused on developing methodologies and tools for the non-destructive assessment of quality of fish products.

Specifically, this task involves:

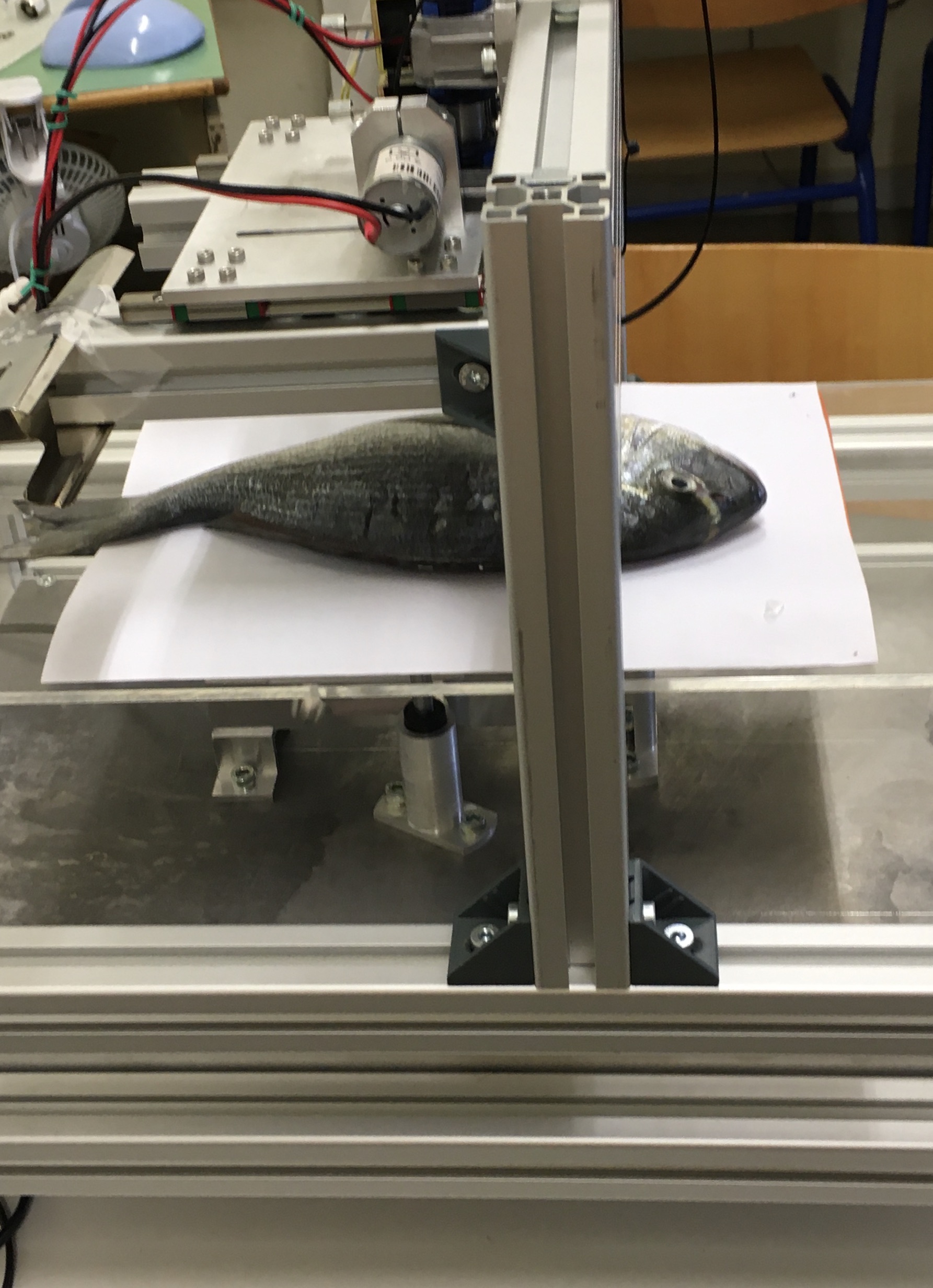

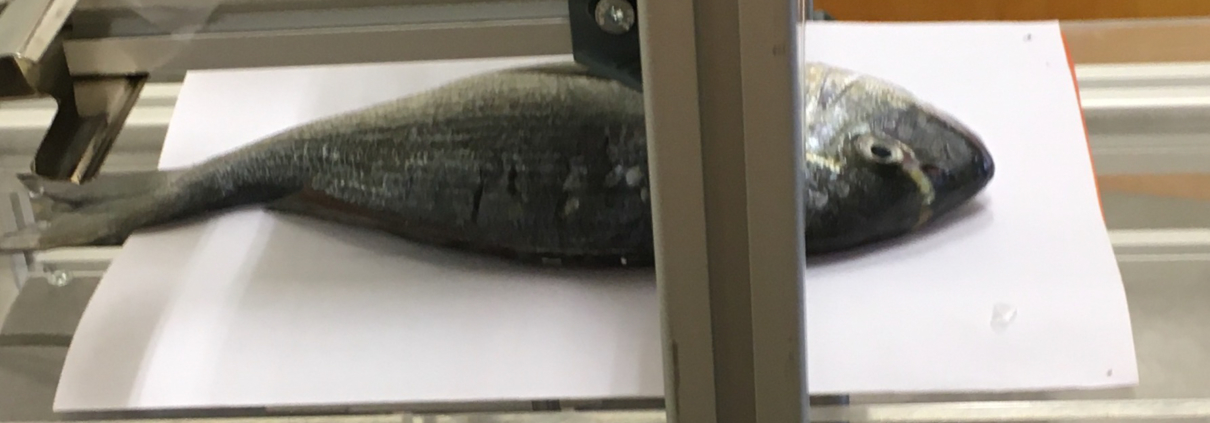

- Building a prototype device for testing commercially available fish using a specific test protocol and logging relevant test data.

- Developing novel algorithms for assessing test data in order to evaluate texture (and hence freshness) of tested fish.

- Performing lab as well as large-scale testing in industrial environment to validate the device operation and results and undertake device/ algorithmic modifications if needed.

- Undertaking process for IP protection of the device

Up to this point, a novel algorithmic operational framework for fish texture evaluation has been recently proposed and published*. This framework postulates a purposely-designed testing protocol applicable to fish products, which combines a vibration-like non-destructive loading of fish under assessment with detailed guidelines for analyzing the fish response data collected from testing.

The outcome allows for quantifying specific parameters related to springiness and viscoelasticity of fish flesh, which, in turn, translates into freshness assessment of tested fish. Published results show that definitive textural changes may be quantified between two fish batches stored in ice for different time intervals (1 and 5 days, respectively). Besides, further testing showed distinction between fish bought on the same day and stored for few hours in different temperatures. This is a promising indication that the same tool may be used for distinguishing among fish batches those exposed to abusive temperature conditions.

*D. Dimogianopoulos and K. Grigorakis, Effective algorithmic operational framework for fish texture evaluation in industry: Achieving maturity, Aquaculture and Fisheries, October 16, 2020, https://doi.org/10.1016/j.aaf.2020.10.001

Figure: Detail of the prototype device during testing

Galaxidi

Galaxidi