Register for the inaugrual ‘On The Horizon’ webinar

On Wednesday 29th September, FutureEUAqua is co-organising a webinar together with EATiP and Horizon 2020 sister projects AquaImpact, iFishIENCi, NewTechAqua and Aqua Excel 3.0.

The webinar is the first in a series aiming to disseminate specific aquaculture project outputs from the EU Horizon Framework programmes and demonstrating support for key objectives including the Strategic Guidelines for competitive and sustainable aquaculture in the EU, the Blue Economy, the European Green Deal and Farm 2 Fork Strategies.

The forum is organised with the support of the Federation of European Aquaculture Producers.

Do you want to attend? Please register here.

Wednesday 29 September:

Agenda (10:00 – 12:00)

Welcome by the EATIP General Secretary, Mr. David Bassett

Introduction by the FEAP President, Mrs. Lara Barazi.

Virtual Aquaculture Laboratory for optimizing experiments with fish and water treatment setups.

Finn Olav Bjørnson | SINTEF Ocean

Dietary effects on growth, survival and behavioural responses in lumpfish  (Cyclopterus lumpus L.) larvae.

(Cyclopterus lumpus L.) larvae.

Ibon García Gallego | ULPGC

Q&A and interactive Mentimeter

Potential of novel and circular based economy raw materials as main ingredients  in salmon diets.

in salmon diets.

Katerina Kousoulaki | NOFIMA

Improving resource efficiency and disease resistance of farmed fish  by selective breeding.

by selective breeding.

Antti Kause | Luke – Natural Resources Institute Finland

Genetic breeding approach to increase efficiency,  reduction, and sustainability.

reduction, and sustainability.

Julianna Kobolak | Hungarian University of Agriculture and Life Sciences (MATE)

Industry data for improved management .

.

Björgólfur Hávarðsson | The Seafood Innovation Cluster Norway

Q&A and interactive Mentimeter

Webinar conclusions

New ingredients fit for feed?

In the search for new, sustainable fish feed ingredients, researchers are working to see if the ingredients can be used in feed technically.

Tor Andreas Samuelsen and colleagues at Nofima in Bergen have a number of advanced techniques in store. Samuelsen says it is underestimated how important it is that new ingredients being introduced to fish feed actually have the correct technical quality. Some ingredients require too much water, others require too high a temperature, while others disrupt the structural properties of the pellet – a bit like when you end up with a failed dough in your kitchen at home.

“If you cannot produce feed with high physical quality, it will crush into pieces before it reaches the fish, and the fish will not be able to eat it”, says Samuelsen.

He has a bag of tunicate meal in front of him on the table. Tunicate meal consists of dried and ground tunicates; a kind of sea squirt which feeds on microalgae in the sea. As part of the EU projects AQUABIOPRO-FIT (funded by BBI JU Horizon 2020) and FutureEUAqua (Horizon 2020) as well as the Swedish VINNOVA-funded project Marine Feed, the researchers have found that tunicate meal meets the nutritional requirements for ingredients that can replace some of the fish and soybean meal commonly used in feed. Tunicate meal is rich in the essential amino acids that fish need to build protein, but there’s still a work to be done to reduce its salt content. Samuelsen has tested the technical quality of tunicate meal and how much can be used in the feed.

Feed analysis with a CT scanner

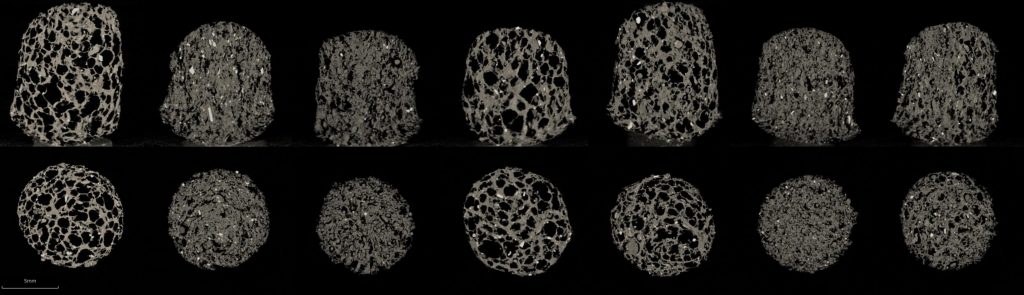

Trial feeds were produced at the feed technology centre in Bergen. First, feed mixtures with different levels of tunicate meal were fed into an extruder, where the mixtures were cooked, kneaded, expanded and dried into pellets with a porous structure. The pores were then filled with rapeseed oil and then subjected to an oil leakage test.

Samuelsen used a CT scanner to examine the microstructure inside the pellet. A CT scanner is an advanced X-ray device which makes it possible to see the 3D structure without slicing the pellet.

“By studying the pellet’s inner structure, we gain a detailed understanding for example on how various ingredients affect the pore structure”, says Samuelsen.

The CT scan showed a large range in pore structure for pellets containing different amounts of tunicate meal. Photo: Gunhild Haustveit © Nofima.

The scan showed that feed pellets with a large percentage of tunicate meal had large pores. The pellet with the largest pores adsorbed the highest amount of oil, but also resulted in highest oil leakage.

Determining the maximum amount of tunicate meal

By running a mixture design experiment in the statistics program, he has set some quality requirements for the pellet when he adds tunicate meal to the feed:

“I want as much tunicate meal as possible in the feed mixture, but the pellet still needs to be of high physical quality and as porous as possible to make it adsorb the necessary quantities of oil. It also needs to have a high water stability.”

He found that 50% of the fish meal could be replaced by tunicate meal without compromising the physical quality of the feed.

Advanced tools

New ingredients that may be interesting to use in fish feed are constantly emerging. The work on tunicate meal is a nice example of how important it is to have advanced tools for studying ingredients and feed, says Samuelsen.

“We need to understand why ingredients differ from each other to be able to model the production process and physical properties of the feed before we start.”

Such new tools are now available through the Aquafeed Technology Centre (ATC) which is hosted by Nofima. This is part of the Norwegian roadmap for research infrastructure which is carried out in cooperation with Norce and the University of Bergen. ATC provides the industry with access to state-of-the-art laboratories and pilot-scale facilities to be able to meet the future needs of research, process and product development.

“ATC gives Nofima a unique opportunity to help the industry develop and characterize new, sustainable ingredients”, says Samuelsen.

This article was first published on nofima.no 27 October 2020.

FutureEUAqua and sustainable innovative tailor-made fish diets

Written by: Elena Mente, Katerina Kousoulaki, Ioannis Nengas

This article was first published on 11 April 2021 in the Feed & Additive Magazine

The ongoing positive growth trend of the aquaculture industry continues, reflecting the rising demand for healthy human food products. Availability of sustainable ingredients in fish feeds is crucial to maintain the increasing demand of the aquaculture industry and the consumers. In FutureEUAqua, resilient fish, efficient in utilizing sustainable innovative tailor-made diets are developed.

European aquaculture production has reached 1.3 million tonnes in volume with a value of over 4 billion euro (EU-28 member states). Of this amount, 4% is certified as organic, amounting in 2015 to a total of approximately 50,000 tonnes (Lembo and Mente, 2019). Nevertheless, significant bottlenecks present in organic farming need to be overcome in order to maintain this positive trend. In 2015, EU consumers spent 54 billion euro for buying fisheries and aquaculture products, reaching the highest amount ever recorded (EUMOFA, 2017).

However, Europe is still heavily dependent on external markets to cover this demand. Thus, EU aquaculture needs to increase the competitiveness of its products and respond to consumer demands for high-quality and safe food, in a challenging context of climate change, greater competition for natural resources, and conflicting interests for space and markets. To ensure food and nutrition security by 2030, the food production sectors have to sustainably expand in terms of space use, production and new value chains, exploring and enhancing innovation opportunities offered by sustainable and resilient aquaculture production systems, implementing the circular economy principles and increasing social acceptance of the corresponding activities and products.

Read the full article for free in the Feed & Additive magazine