Get to know: Kefalonia Fisheries S.A.

We asked Ms. Evi Abatzidou to tell her story about Kefalonia Fisheries. Here is what she has to say.

Please briefly introduce your company and what you do at the company

Kefalonia Fisheries S.A., established in 1981, is a global leader in the farming and distributing Mediterranean Aquaculture products of high quality with high environmental responsibility. During the 3.5 decades of operation, KF has always been a pioneer in the development of aquaculture production and marketing strategies that makes the company one of the most competitive and profitable in the sector. Some milestones of the company are: (1) First aquaculture company that produced sea bass and sea bream in Greece, (2) First company with vertical production of sea bass and sea bream, with complete traceability in all production stages, from egg to final product (fish), (3) First aquaculture company certified for organic production of sea bass and sea bream in Greece, (4) Award-winning company with the Superior Taste Award Certification of (international Taste & Quality institute) for sea bass.

At the moment, Kefalonia Fisheries employs more than 200 people, produces and sells over 5 million of fry and over than 5.000 tons of sea bass and sea bream. The annual sales of the company exceed 30 million Euros. More than 80% of the production is exported, mostly in Italy, France, U.A.E., U.S.A and others (more than 15 more countries).

The company owns a number of certifications related to the ensuring the quality, safety and sustainability of the production. Such certifications are: ISO 9001, ISO 14001, ISO 22000, Fish from Greece, Global G.A.P., Friends of the sea for sustainable Fisheries and Aquaculture, ASC, Naturland e.V. and the EU organic standard for organic aquaculture.

I work in Kefalonia Fisheries since 1986 and I am responsible for fry production and the R&D department. I oversee all aspects of the hatchery, including the management of personnel, fish and equipment. I track the fish cycles to determine harvest and release time. I am also responsible for our breeding program and fry quality. Since 2015, I supervise all research programs of our company.

Why do you find it important to participate in H2020 projects? What are the benefits for you ?

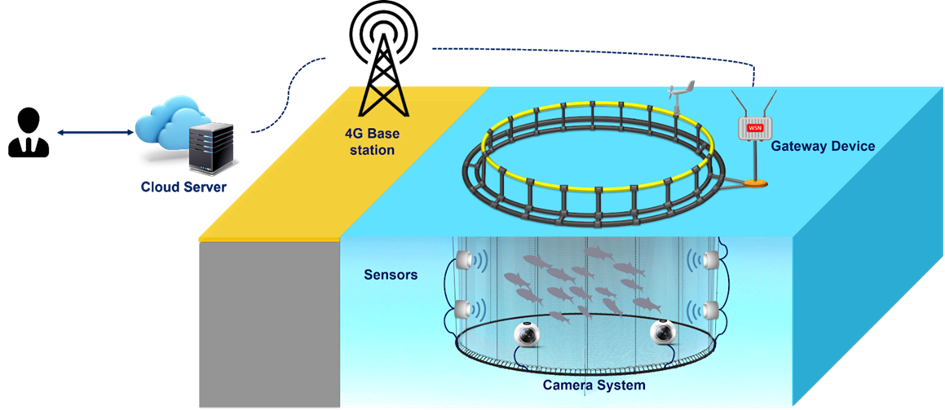

With particular interest in the continuous improvement of production techniques, the efficient population management in farms, the advancement of the nutritional profile of the final product, the development of sustainable practices and the welfare of fish, Kefalonia Fisheries has participated in several national and European research projects, regarding the development of new sea bass and sea bream products, biotechnology for the growth and the exploitation of micro- and macro- algae, the use of new technologies for the quality control and the sustainable management of aquaculture and the quality control of the final product.

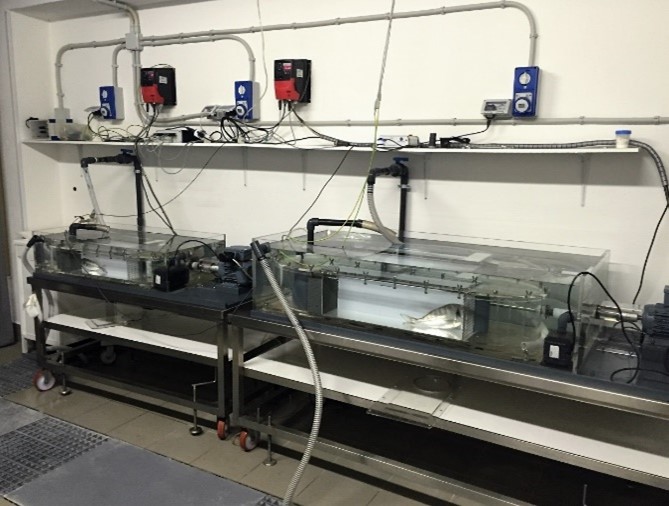

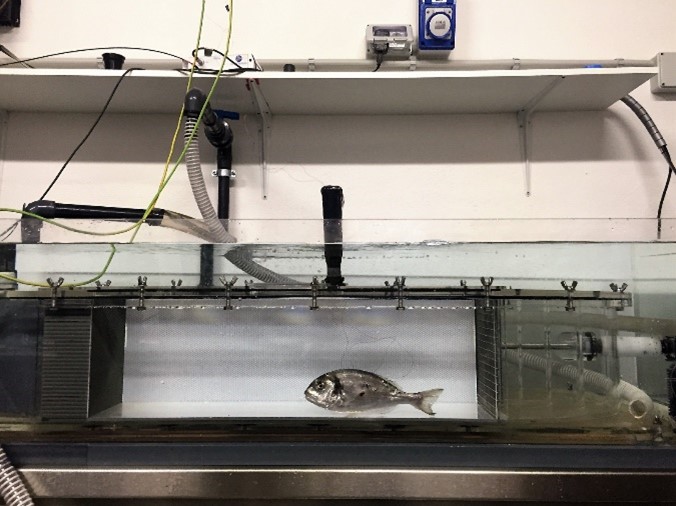

Our participation in Future EUaqua project was focused mainly on large scale feeding trials using innovative, sustainable, conventional and organic feeds. This is just one task of the project among many others, like: sustainable breeding, innovative optimal production systems, monitoring technologies of the environmental impact on fish health and welfare, consumer awareness, etc.

We find that H2020 platform provides us with the perfect innovative tools, helping us to fulfill all our goals.

What are your main challenges and how the project can contribute to overcome these?

Our company’s main interests and research pillars are always sustainability, circular economy, innovation, quality and fish welfare. Horizon 2020 couples innovation and research, giving emphasis on excellent science and industrial leadership, thus creating the perfect platform for promoting our interests. Combining the industrial work and public research in multidisciplinary consortia of RTD Centers, large companies, SMEs and Associations, H2020 programs deliver innovation by tackling a large spectrum of societal challenges.

Participating in Horizon 2020 program, provides us with the cutting edge knowledge and innovative technology, which is essential in keeping us competitive at a global level.