Get to know: Kefalonia Fisheries S.A.

We asked Ms. Evi Abatzidou to tell her story about Kefalonia Fisheries. Here is what she has to say.

Please briefly introduce your company and what you do at the company

Kefalonia Fisheries S.A., established in 1981, is a global leader in the farming and distributing Mediterranean Aquaculture products of high quality with high environmental responsibility. During the 3.5 decades of operation, KF has always been a pioneer in the development of aquaculture production and marketing strategies that makes the company one of the most competitive and profitable in the sector. Some milestones of the company are: (1) First aquaculture company that produced sea bass and sea bream in Greece, (2) First company with vertical production of sea bass and sea bream, with complete traceability in all production stages, from egg to final product (fish), (3) First aquaculture company certified for organic production of sea bass and sea bream in Greece, (4) Award-winning company with the Superior Taste Award Certification of (international Taste & Quality institute) for sea bass.

At the moment, Kefalonia Fisheries employs more than 200 people, produces and sells over 5 million of fry and over than 5.000 tons of sea bass and sea bream. The annual sales of the company exceed 30 million Euros. More than 80% of the production is exported, mostly in Italy, France, U.A.E., U.S.A and others (more than 15 more countries).

The company owns a number of certifications related to the ensuring the quality, safety and sustainability of the production. Such certifications are: ISO 9001, ISO 14001, ISO 22000, Fish from Greece, Global G.A.P., Friends of the sea for sustainable Fisheries and Aquaculture, ASC, Naturland e.V. and the EU organic standard for organic aquaculture.

I work in Kefalonia Fisheries since 1986 and I am responsible for fry production and the R&D department. I oversee all aspects of the hatchery, including the management of personnel, fish and equipment. I track the fish cycles to determine harvest and release time. I am also responsible for our breeding program and fry quality. Since 2015, I supervise all research programs of our company.

Why do you find it important to participate in H2020 projects? What are the benefits for you ?

With particular interest in the continuous improvement of production techniques, the efficient population management in farms, the advancement of the nutritional profile of the final product, the development of sustainable practices and the welfare of fish, Kefalonia Fisheries has participated in several national and European research projects, regarding the development of new sea bass and sea bream products, biotechnology for the growth and the exploitation of micro- and macro- algae, the use of new technologies for the quality control and the sustainable management of aquaculture and the quality control of the final product.

Our participation in Future EUaqua project was focused mainly on large scale feeding trials using innovative, sustainable, conventional and organic feeds. This is just one task of the project among many others, like: sustainable breeding, innovative optimal production systems, monitoring technologies of the environmental impact on fish health and welfare, consumer awareness, etc.

We find that H2020 platform provides us with the perfect innovative tools, helping us to fulfill all our goals.

What are your main challenges and how the project can contribute to overcome these?

Our company’s main interests and research pillars are always sustainability, circular economy, innovation, quality and fish welfare. Horizon 2020 couples innovation and research, giving emphasis on excellent science and industrial leadership, thus creating the perfect platform for promoting our interests. Combining the industrial work and public research in multidisciplinary consortia of RTD Centers, large companies, SMEs and Associations, H2020 programs deliver innovation by tackling a large spectrum of societal challenges.

Participating in Horizon 2020 program, provides us with the cutting edge knowledge and innovative technology, which is essential in keeping us competitive at a global level.

New ingredients fit for feed?

In the search for new, sustainable fish feed ingredients, researchers are working to see if the ingredients can be used in feed technically.

Tor Andreas Samuelsen and colleagues at Nofima in Bergen have a number of advanced techniques in store. Samuelsen says it is underestimated how important it is that new ingredients being introduced to fish feed actually have the correct technical quality. Some ingredients require too much water, others require too high a temperature, while others disrupt the structural properties of the pellet – a bit like when you end up with a failed dough in your kitchen at home.

“If you cannot produce feed with high physical quality, it will crush into pieces before it reaches the fish, and the fish will not be able to eat it”, says Samuelsen.

He has a bag of tunicate meal in front of him on the table. Tunicate meal consists of dried and ground tunicates; a kind of sea squirt which feeds on microalgae in the sea. As part of the EU projects AQUABIOPRO-FIT (funded by BBI JU Horizon 2020) and FutureEUAqua (Horizon 2020) as well as the Swedish VINNOVA-funded project Marine Feed, the researchers have found that tunicate meal meets the nutritional requirements for ingredients that can replace some of the fish and soybean meal commonly used in feed. Tunicate meal is rich in the essential amino acids that fish need to build protein, but there’s still a work to be done to reduce its salt content. Samuelsen has tested the technical quality of tunicate meal and how much can be used in the feed.

Feed analysis with a CT scanner

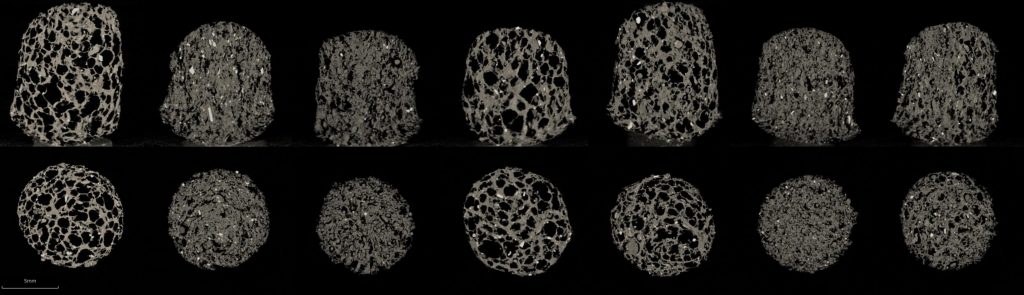

Trial feeds were produced at the feed technology centre in Bergen. First, feed mixtures with different levels of tunicate meal were fed into an extruder, where the mixtures were cooked, kneaded, expanded and dried into pellets with a porous structure. The pores were then filled with rapeseed oil and then subjected to an oil leakage test.

Samuelsen used a CT scanner to examine the microstructure inside the pellet. A CT scanner is an advanced X-ray device which makes it possible to see the 3D structure without slicing the pellet.

“By studying the pellet’s inner structure, we gain a detailed understanding for example on how various ingredients affect the pore structure”, says Samuelsen.

The CT scan showed a large range in pore structure for pellets containing different amounts of tunicate meal. Photo: Gunhild Haustveit © Nofima.

The scan showed that feed pellets with a large percentage of tunicate meal had large pores. The pellet with the largest pores adsorbed the highest amount of oil, but also resulted in highest oil leakage.

Determining the maximum amount of tunicate meal

By running a mixture design experiment in the statistics program, he has set some quality requirements for the pellet when he adds tunicate meal to the feed:

“I want as much tunicate meal as possible in the feed mixture, but the pellet still needs to be of high physical quality and as porous as possible to make it adsorb the necessary quantities of oil. It also needs to have a high water stability.”

He found that 50% of the fish meal could be replaced by tunicate meal without compromising the physical quality of the feed.

Advanced tools

New ingredients that may be interesting to use in fish feed are constantly emerging. The work on tunicate meal is a nice example of how important it is to have advanced tools for studying ingredients and feed, says Samuelsen.

“We need to understand why ingredients differ from each other to be able to model the production process and physical properties of the feed before we start.”

Such new tools are now available through the Aquafeed Technology Centre (ATC) which is hosted by Nofima. This is part of the Norwegian roadmap for research infrastructure which is carried out in cooperation with Norce and the University of Bergen. ATC provides the industry with access to state-of-the-art laboratories and pilot-scale facilities to be able to meet the future needs of research, process and product development.

“ATC gives Nofima a unique opportunity to help the industry develop and characterize new, sustainable ingredients”, says Samuelsen.

This article was first published on nofima.no 27 October 2020.

Webinar for stakeholders: Aquaculture and IoT

How Internet of Things can enhance aquaculture farms productivity and ensure sustainability ?

25th February 2021

2.00pm CET (Berlin/Paris time) via Zoom

by Dr. Sébastien Alfonso (COISPA Tecnologia & Ricerca)

Objective of the webinar

- To learn about the potential of the Internet of Things (IoT) to address the challenges of a sustainable and resilient aquaculture system.

About the webinar

- 1 hour event dedicated to the members of the Stakeholder Platform.

- 45 minutes presentation and 15 minutes Q&A session with experts.

If you are interested in joining the webinar, please register here.

For more information

- Zsófia Kertész (Campden BRI Hungary): z.kertesz@campdenkht.com

- Åsa Maria O. Espmark (Nofima): Asa.Espmark@Nofima.no

- Magnus Ljung (Swedish University of Agricultural Sciences): Magnus.Ljung@slu.se

The webinar will be recorded. By joining, you are giving consent for this webinar to be recorded.